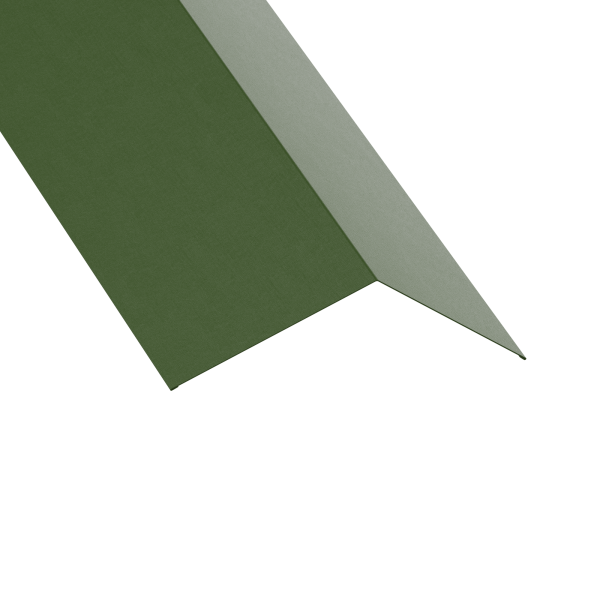

3.000m long, Ridge Cap, 200mm x 200mm x 120°, Plastic Coated

Technical Specifications

- Length - 3.000m

- Dimensions - 200mm x 200mm

- Angle - 120deg

- Finish - Leathergrain Plastic Coating

- Material - Galvanised Steel

- Thickness - 0.7mm

- Weight - 6.24kg

- Colour Side - External

- Lap - 100mm mimimum

- Edges - Welted

- 3.000m ridge cap

- 200mm x 200mm x 120deg.

- Welted

- Available in Juniper Green (BS 12B29) & Goosewing Grey (BS 10A05)

- Plastic coated

- Lightweight & easy to handle

- Easy to install

- Colour matched to sheets

- Plastic coated for a stronger finish

- Welted for extra rigidity

How much should I lap the ridges over one another?

You should have a minimum of 150mm for lapping the ridges.

Do I just fix it down with the top run of main fixings?

No, you want to use the stitchers screws to stitch the ridge to the highest point of the profile on the sheet.

How do I know what angle ridge cap I need?

To work out the ridge angle, you will need to work out the angle of each slope (commonly the same each side on apex buildings). You then minus the two angles from 180° degrees to give you the angle of ridge you need. E.g. if you have an equal apex roof with 30° it would be 180° - (30° + 30°) = 120°.

Is there any flexibility in the ridge flashing?

There is a small amount of flexibility in the ridge, so if you are using our 120° stock ridge you will be able to flex it some degrees either way.

Can I get different sized flashings?

Yes, we can manufacture made to order flashings. If you want to make an enquiry, please contact our sales team.

Can Southern Sheeting cut flashings?

Southern Sheeting will not cut stock flashings. Made to order flashings can be cut to different lengths and girths.

Find the right materials and support for your project

We can help! View our supportive help guides and videos.

Our supportive guides and help videos will help you achieve the best results. Our knowledgeable team can also offer helpful tips, and support to help you plan and purchase what you need!